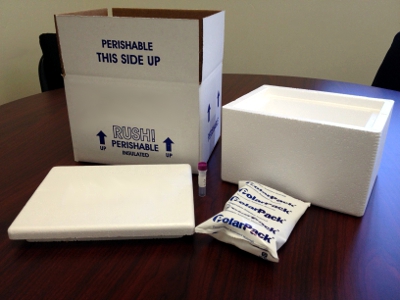

Abcore is in the process of transitioning our packaging materials to minimize waste. This was a concern we have wanted to address since our founding, and we finally found the best solution. We have been using industry standard insulated foam inner boxes, packing peanuts, and surrounded by an outer corrugated cardboard box. While this works well, it is a large amount of packaging and materials for sending out small, microliter volumes of antibodies.

We set the goal of finding new packaging which offered the same insulating protection for our sensitive shipments, but it needed to be smaller, lighter, less wasteful, and better on the environment. We received samples from a number of companies for review. Following user and quality testing, we decided on new metalized polyester insulated pouches.

The new metalized polyester insulated pouches are non-toxic, re-useable, and made of 100% sustainable materials. The insulation is made of 100% sustainable polyurethane foam. Best of all, it is small enough to fit inside a standard FedEx Pak. It is almost 60% lighter and is only a fraction of the size. We sent test shipments with sample test tubes to locations in North America and all tests arrived cold and ready for use upon delivery.

We are very excited to transition to using our new insulated pouches for all our shipments. We have a large number of boxes we need to get through before we can say we are 100% converted, but at the rate we are shipping it should not take long! We also can’t wait to use the new insulated pouches because if you didn’t hear the news, Abcore has started selling our own line of antibodies.

Shipping is the first impression people receive of your product, and nothing is worse than getting a massive amount of shipping peanuts, paper, cardboard, and styrofoam for a small aliquot of antibody. That is certainly not the first impression that we want to give to our end users. We strive to be innovative at Abcore, and we hope that this is a change that the entire industry soon embraces.